- Home Page

- Company Profile

-

Our Products

- Neutral Grounding Resistor

- Loading Neutral Grounding Resistors

- Rod Grid Type Neutral Grounding Resistor

- Neutral Grounding Resistor

- Punched Stainless Steel Grids Type NGR

- Formed Stainless Steel Grid type NGR

- Cast Iron Grid Type NGR

- Wire Wound Grid Type Neutral Grounding Resistor

- Punched SS Grid Type NGR

- Buffer Stainless Steel Grid Type NGR

- Wire Grid Type NGR

- Stainless Steel Grid Type NGR

- Generator Neutral Grounding Resistor

- Transformers Neutral Grounding Resistor

- Rod Grid Type NGR

- 22 kV Neutral Grounding Resistor

- 33 kV Neutral Grounding Resistor

- Neutral Grounding Resistor With VC Panel

- Formed Stainless Steel (FSS Grid) Type Neutral Grounding Resistor

- Neutral Grounding Resistor With Monitoring Failsafe Relay

- NGR NIS Panel Neutral Grounding

- Punched Grid Type Neutral Grounding Resistor

- Punched Patti Grid Type Neutral Grounding

- Neutral Grounding Resistor With Pulsating Circuit

- NGTR Panel-Loading Resistor

- Neutral Earthing Resistor

- Wire Grid Type Neutral Grounding Resistor

- Wire Wound Type Neutral Grounding Resistor

- Neutral Earthing Resistors

- Speed Control Resistor

- Buffer Resistors

- Electrical Isolator

- 33 KV Electrical Isolator

- High Voltage Isolators

- OFF Load Indoor Panel Mounted Isolator

- ON Load Indoor Panel Mounted Isolator

- NER Panel

- Neutral Earthing Resistor for Transformer

- Neutral Grounding Resistor

- NGR Panel fof Transformer

- NGR Panel for DG Set

- NGR Panel

- NGR-NIS Panel for DG set

- NGR-NIS Panel

- Load Bank

- Isolation Panels

- Indoor Isolators

- Motor Starting Resistor

- AC Resistive Load Bank

- LAVT and LA-SC-PT Panels

- Grounding Panel

- Switch Panels

- LAVT Panel

- Discharge Resistors

- Isolator LBS Panel

- Neutral Grounding Resistor

- Contact Us

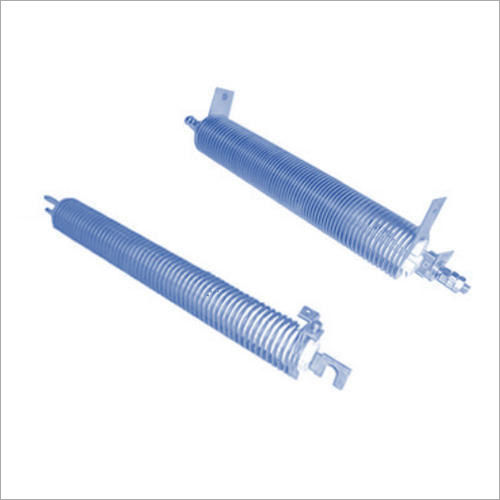

Starting Resistors

500000.00 INR/Unit

Product Details:

- Connector Type Bolt/Terminal type

- IP Rating IP23

- Surface Finish Powder Coated

- Feature Heat Resistant, Durable, High Stability

- Shape Rectangular

- Operating Temperature -20C to 60C

- Overheating Protection Available (via Thermal Switch)

- Click to View more

X

Starting Resistors Price And Quantity

- 500000.00 INR/Unit

- 1 Unit

Starting Resistors Product Specifications

- Resistive

- Powder Coated

- Metal Core / Alloy (Based on general starting resistor construction)

- Bolt/Terminal type

- IP23

- Rectangular

- Customized (Varies per order)

- Standard / As per requirement

- 50 Hz

- Heat Resistant, Durable, High Stability

- For Maintaining Power

- Three Phase

- Available (via Thermal Switch)

- IP23

- Ceramic/Porcelain

- 220-440 Volt (V)

- 95%

- High

- 220-440 V

- Resistors

- -20C to 60C

- Yes

- Terminal Type

- Grey

- Floor/Panel Mounted

Starting Resistors Trade Information

- 100 Unit Per Month

- 1-5 Week

- All India

Product Description

We are offering Starting/Speed Control Resistor. For starting / Speed Control of A.C or D.C. Motors, resistors are manufactured as per customers requirement at specified starting torque or for limiting initial inrush current to an acceptable value. Mainly these are used for cranes. Rating can be 2 minute, 5 minute, 10 minute, continuous or intermittent. Material of resistor is normally Stainless steel AISI-304, AISI -410 or AISI 430 or FeCrAl-AISI-406.

Standards Followed:

- IPSS-1-10-002-82 with amendment no.1 and BS 587 for starting / speed control resistor.

- IS 2147 & IS 12063 of 1987 for degree of protection for enclosure.

- IS 5 for paint shade.

- Any other standard as required can also be followed

TESTS:-

(A). ROUTINE TESTS: - FOLLOWING TESTS WILL BE CONDUCTED.

- Visual and Dimensional

- Insulation resistance value measurement by using 500V megger before and after dielectric test.

- Resistance value measurement with + 10 % tolerance.

- H.V. Test of twice the rated voltage +1000 volts for voltage class below 660 volts.

TYPE TESTS:-

Temperature rise test i.e., Heat run test if required will be conducted by passing equivalent / rated current for rated / equivalent time keeping IT Constant through a part of Resistor.

Starting / Speed Control resistor Product Information:

- Rotor volts at standstill.

- Rotor Current at full load.

- Duty rating (Time on / off No. of Cycles).

- Starting Torque in percentage of full load Torque.

- Material of Resistor.

- No. of steps / sections and its resistance values per phase.

- Type of enclosure (Protection Class as per IS-12063).

- Temperature rise allowed.

- Whether terminals should be brought down at one place.

- Details of atmospheric conditions at site.

Engineered for Heavy-Duty Applications

Starting Resistors provide reliable control for motors in applications such as cranes, hoists, and lifts. With customizable designs, these units offer optimal resistive output, ensuring safe current regulation and system protection during power-on. Their high stability and robust construction make them the preferred choice in industrial settings.

Durable and Safe Performance

Built to last over a decade, these resistors are designed with advanced thermal switches for overheating protection, ceramic or porcelain insulation, and powder-coated surfaces. This combination enhances durability, safety, and resistance to harsh operating conditions including high humidity and vibration.

FAQs of Starting Resistors:

Q: How are Starting Resistors installed in industrial applications?

A: Starting Resistors are typically mounted on the floor or on control panels using terminal or bolt-type connectors. Their dimensions can be customized according to space and application requirements, ensuring seamless integration into your system.Q: What benefits do these resistors provide to motor starting systems?

A: They regulate initial current flow to motors, preventing overload and reducing mechanical stress during startup. This prolongs motor lifespan and enhances operational stability, especially in high-demand applications like cranes and lifts.Q: When should overheating protection be considered for these resistors?

A: Overheating protection, provided by integrated thermal switches, should be considered in applications with high operational cycles or where the ambient temperature may rise above normal conditions. This feature ensures safe operation and prevents equipment damage.Q: Where can these resistors be utilized effectively?

A: They are optimal for industrial machinery, including cranes, hoists, elevators, and any motor starting scenarios requiring precise power control and high stability. Their robust design makes them ideal for both indoor and sheltered outdoor setups.Q: What is the manufacturing process for customized resistor units?

A: Production begins with selecting appropriate metal core or alloy materials, followed by shaping them according to customized dimensions. The resistors are then insulated with ceramic or porcelain and finished with a powder-coated surface to ensure durability and heat resistance.Q: How long do these resistors typically last in operation?

A: Thanks to their high-quality materials and compliance with IS/IEC standards, these resistors have a lifespan of more than 10 years, even under demanding industrial conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Speed Control Resistor' category

"We mainly deals in export markets as Nepal, Kenya, Yemen, Saudi Arabia, Dubai, Riyadh, Sudan, Iraq, Singapore, Vientiane, Bangkok, Manila, Nigeria, Africa, Malaysia, Syria, Amman, Jordan, Iraq, Thailand, Zambia, Rwanda At East Africa, Lusaka, Zambia, Jakarta, West Africa & Ethiopia."

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese